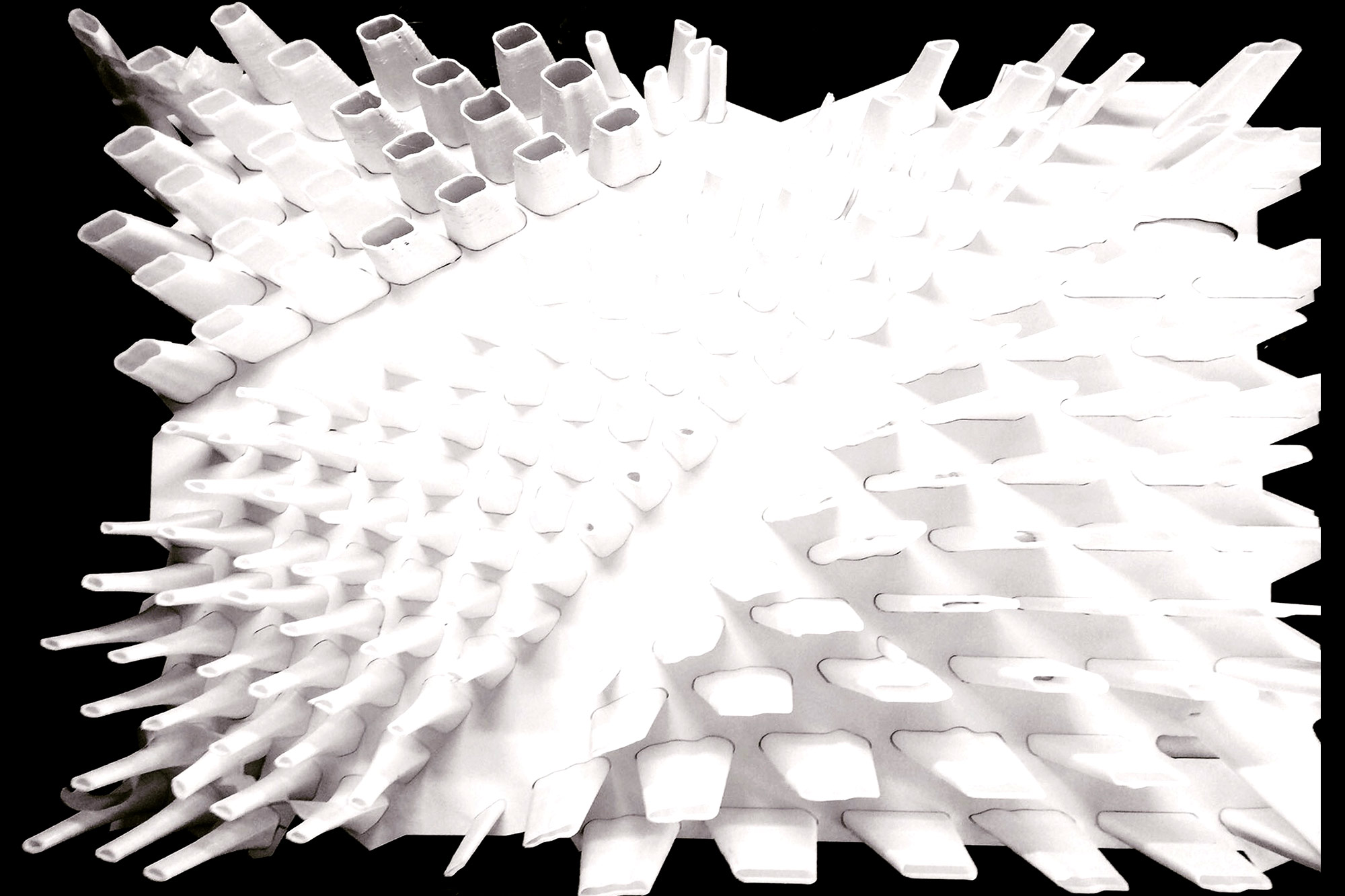

The team developed this work, starting from an original scanned stamp, which was given volume through visual programming in Grasshopper. During more than four months the 3D printing of all the pieces that compose it was carried out and then put in place on a template made with laser cutting. There were 5 3D printers and a robot arm printing pieces in white PLA every day to reach the appointed date. The material chosen for 3D printing was PLA, because it allows 3D printing at a higher speed than other materials such as ABS.

Project data

Client:Royal National Coin and Stamp Factory

Research team: Fabricio Santos, Miguel Carmona, José Real, Adolfo Nadal, Roque Peña, Alborán Fatou y Eduardo González Requeijo.

Project management: FAB LAB UE – European University Madrid

Manufacturing partners: EXarchitects, FABdeFAB.

Collaborators: ANFIL, Post Office

Techniques: 3D printer, industrial robot, laser cutting.