For the renovation of the entrance hall of the NH Berlin Alexanderplatz, Sulitze Muñoz contacted EXarchitects to carry out the parameterization and fabrication of a single piece that would cover an existing pillar in the middle of the entrance hall.

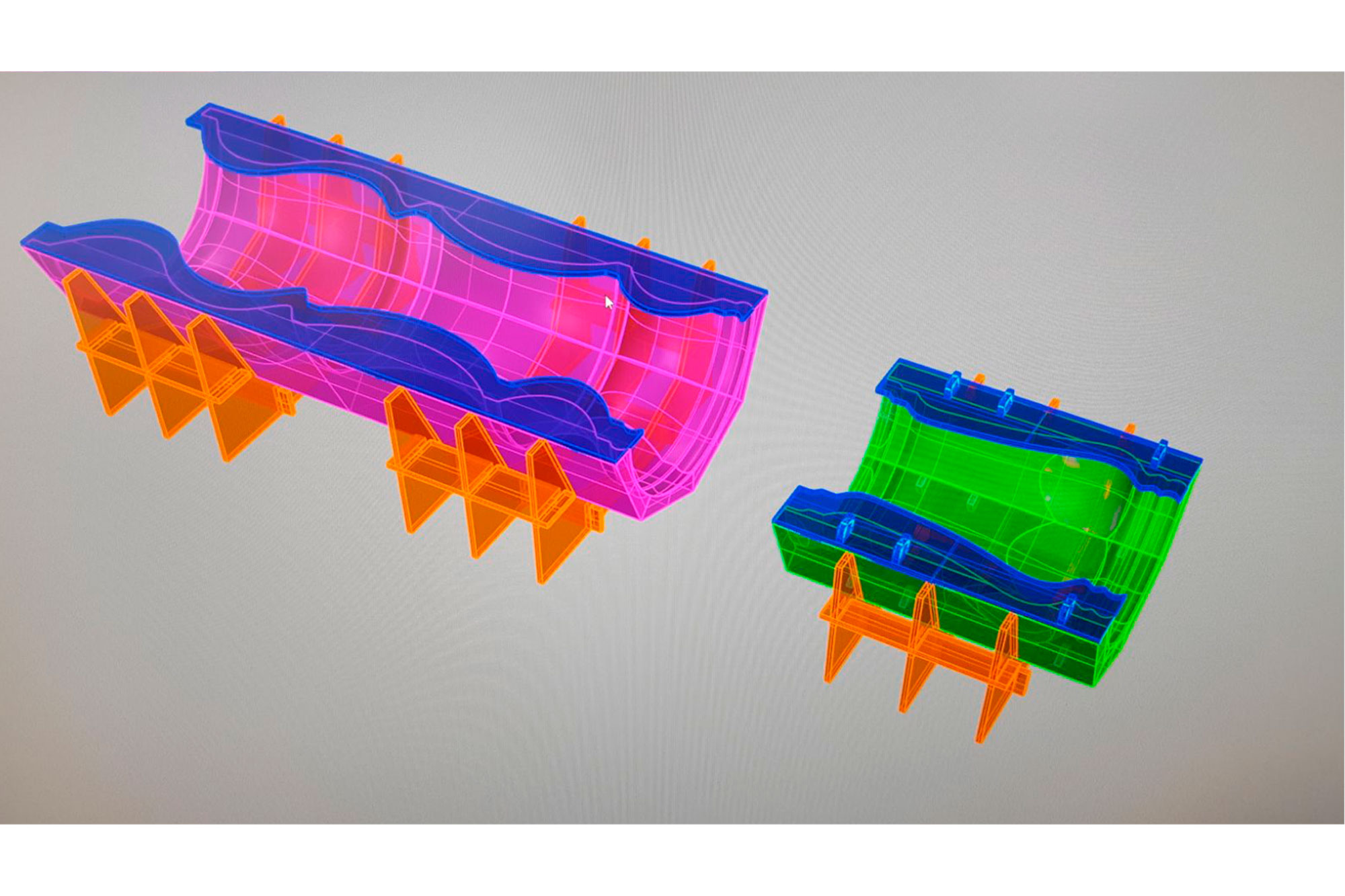

Once the mold was made using digital fabrication techniques, the parts were fibrillated and then lacquered and painted in Madrid and shipped to Berlin. During the manufacture of the mold, a modification of the project arose that required the mold to be enlarged by a few centimeters. As the mold had been manufactured with this possibility in mind, it was rectified using a robot equipped with a milling cutter to avoid having to disassemble the molds. The robotic arm allows us to use 6 axes to operate the milling cutter, as opposed to the traditional 3 of a conventional CNC.

Project data

Project: Pillar manufacturing NH Berlin Alexanderplatz

Interior Design: Sulitze Muñoz

Software used: Rhinoceros + GrassHopper

Year: 2018 – 2019

Parametrization: EXarchitects

Materials: Mold made of MDF wood, fiberglass parts.

Fiberglass: RB composites

Digital fabrication technique: CNC milling in the EXarchitects fablab + CNC milling with Nieto 3D Robot

Montaje en Berlín: EXarchitects