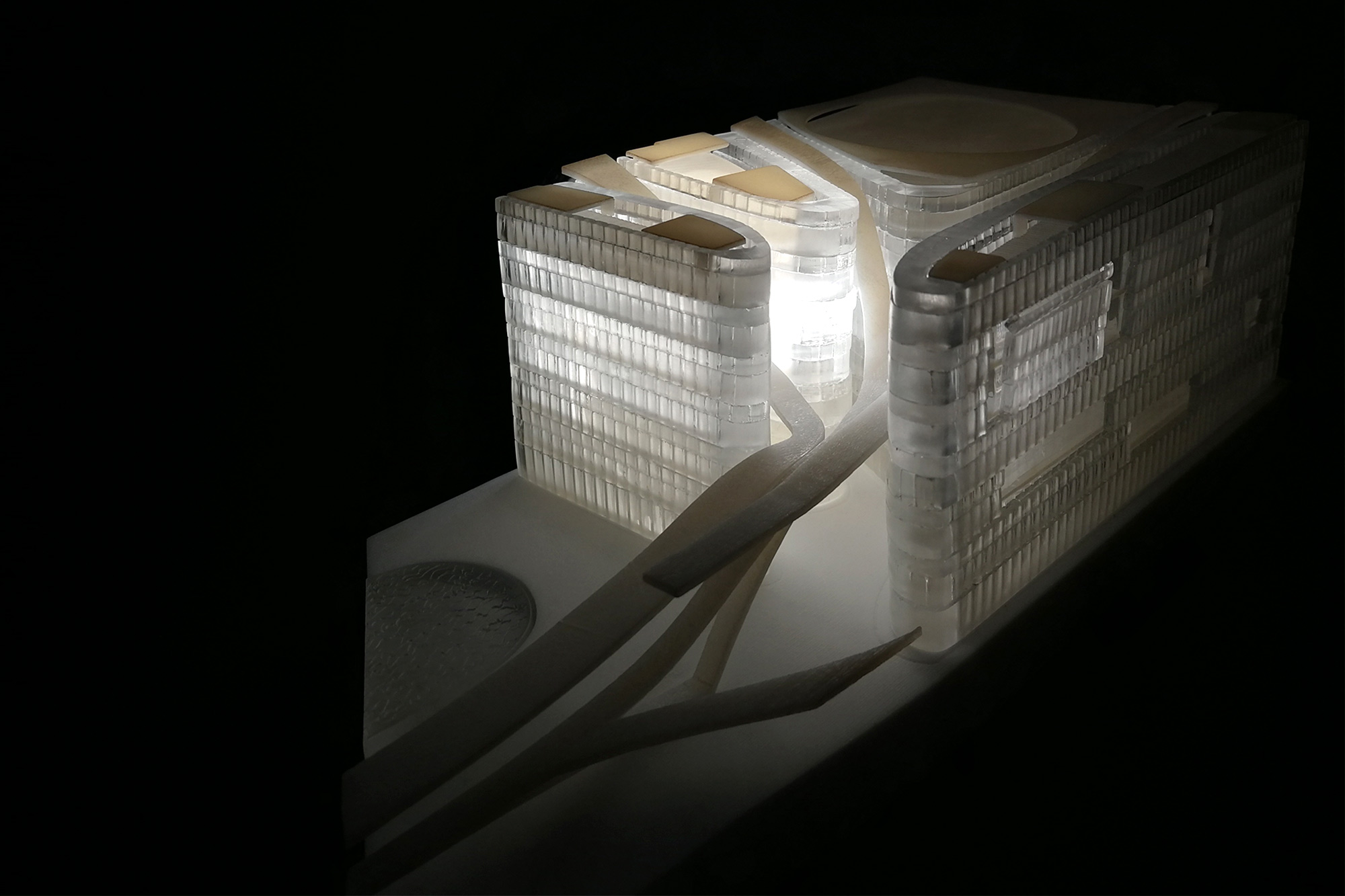

The architectural team formed by Andrés Perea, Elena Suárez and Rafael Torrelo Arquitectos, commissioned the EXarchitects team to make a model for a proposal in an international architectural competition II. Once we received the information and the base planimetry, our team began to plan and manufacture it in our fablab in Villaviciosa de Odón.

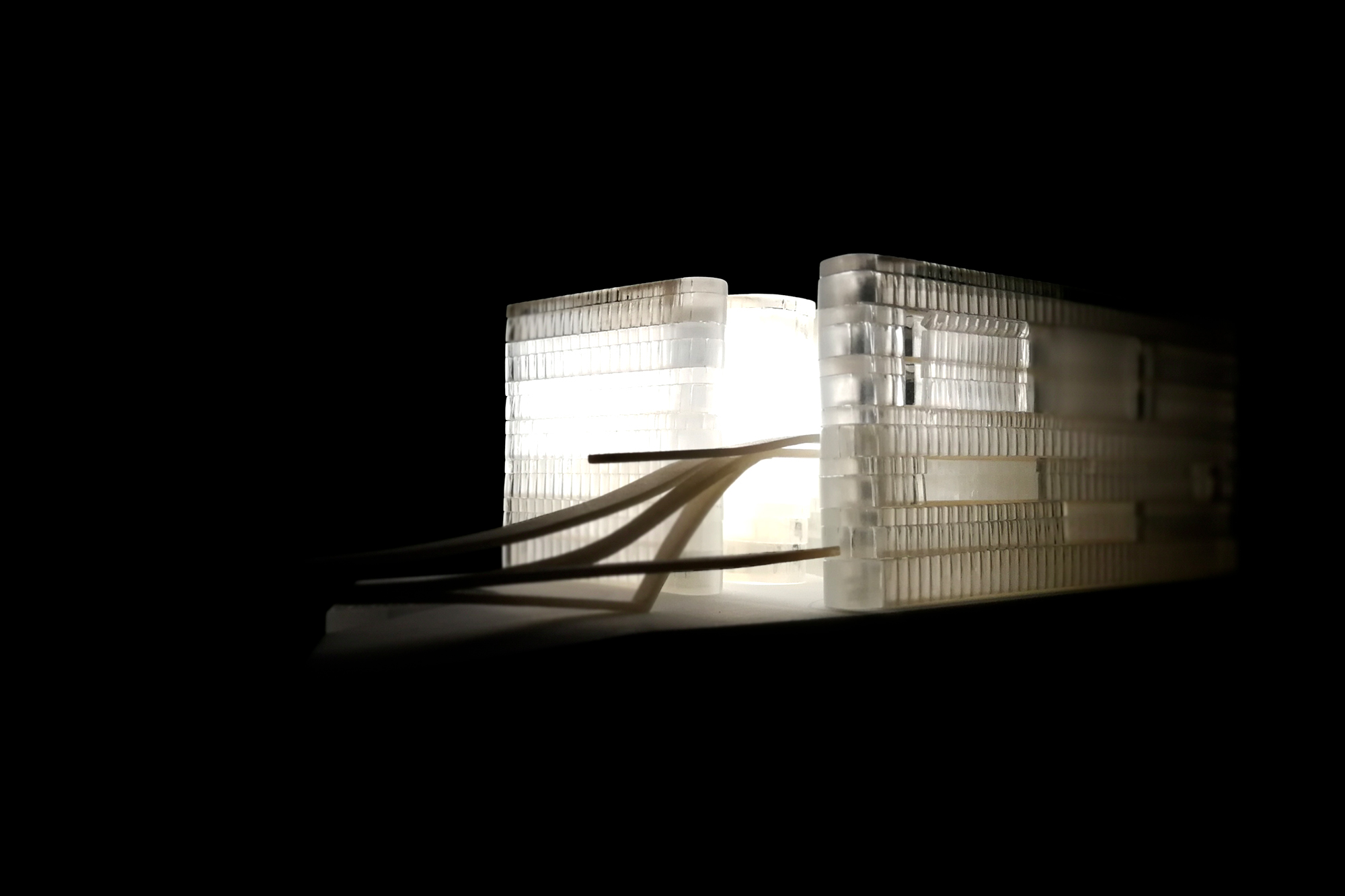

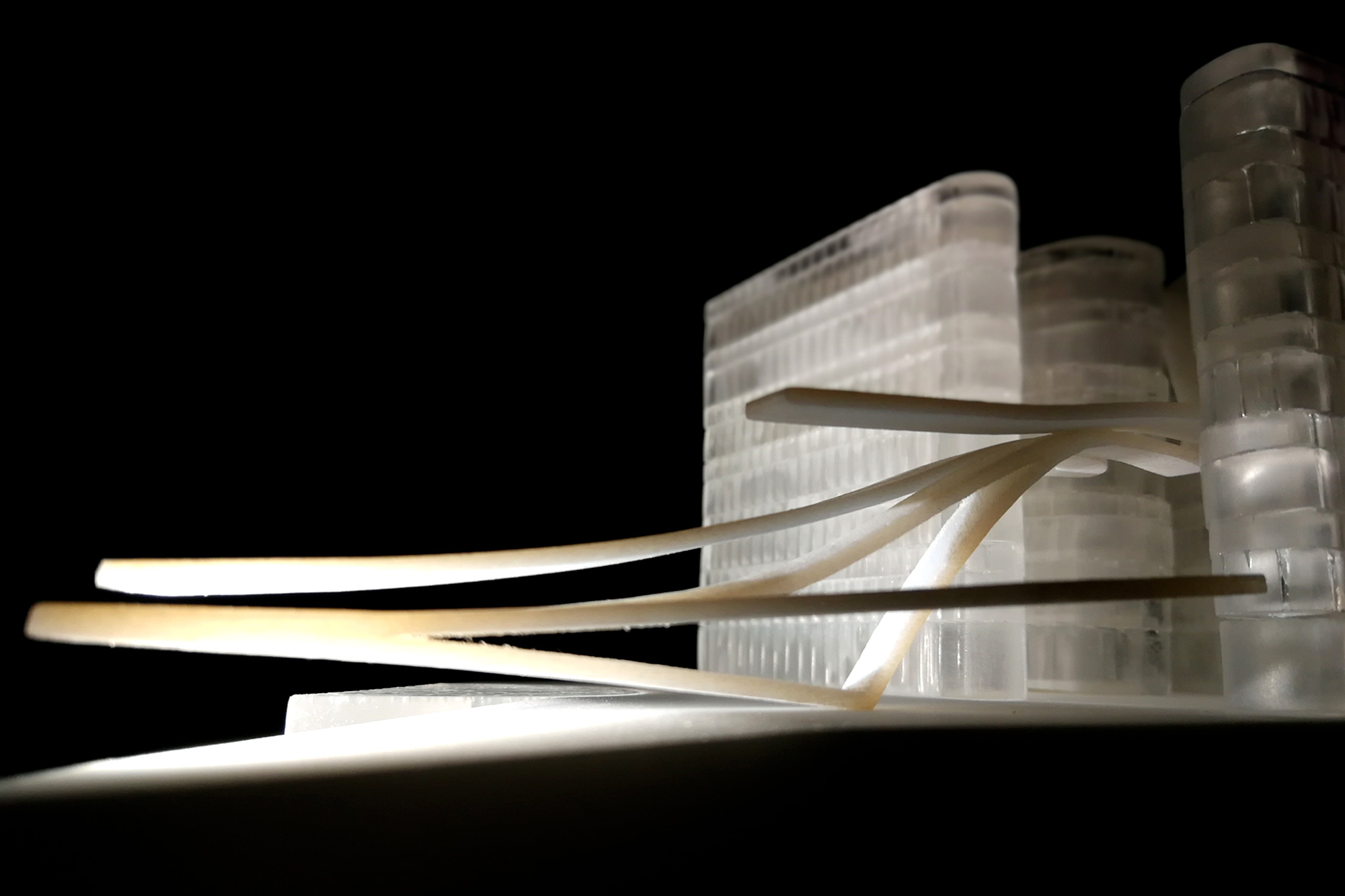

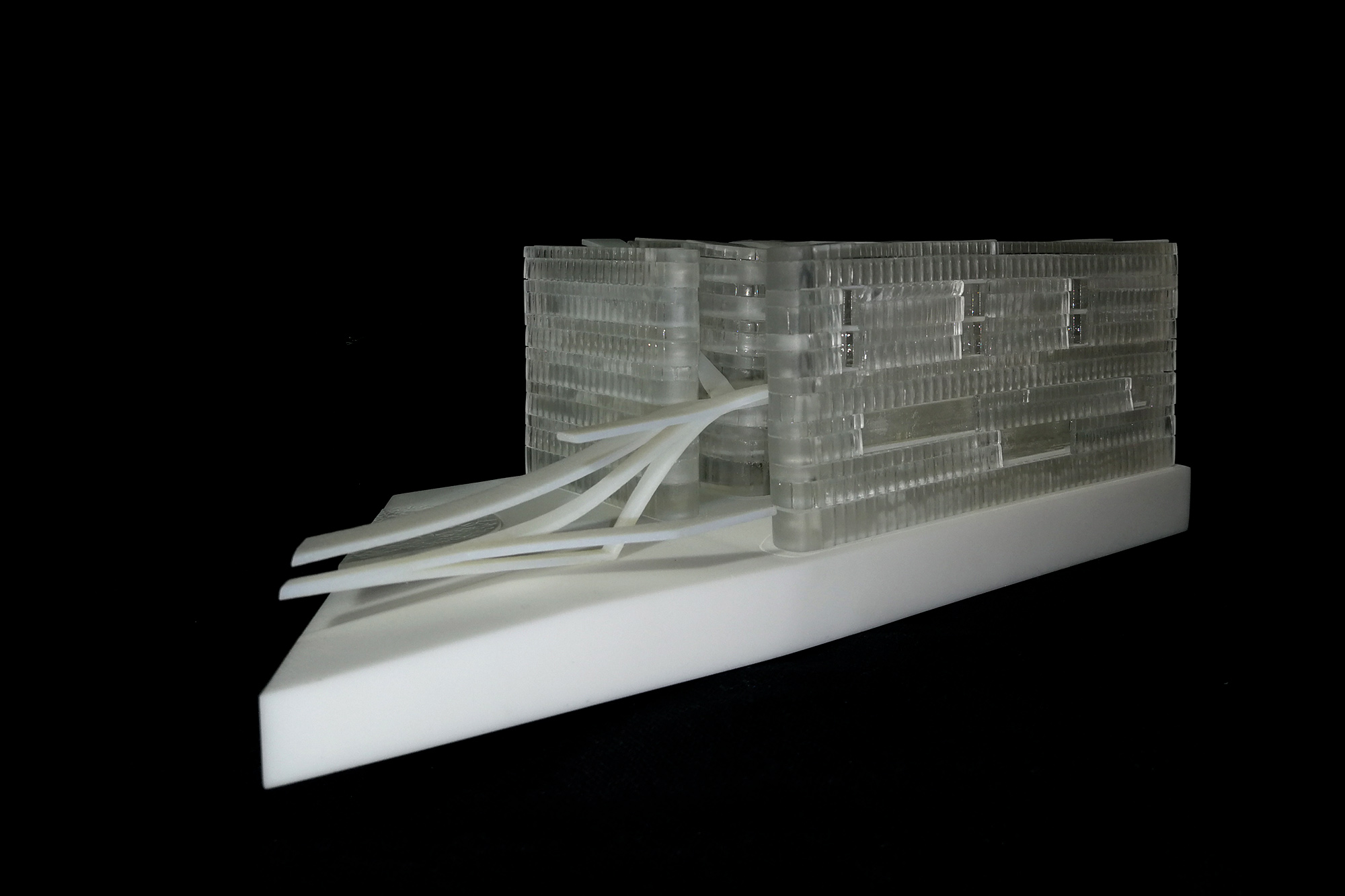

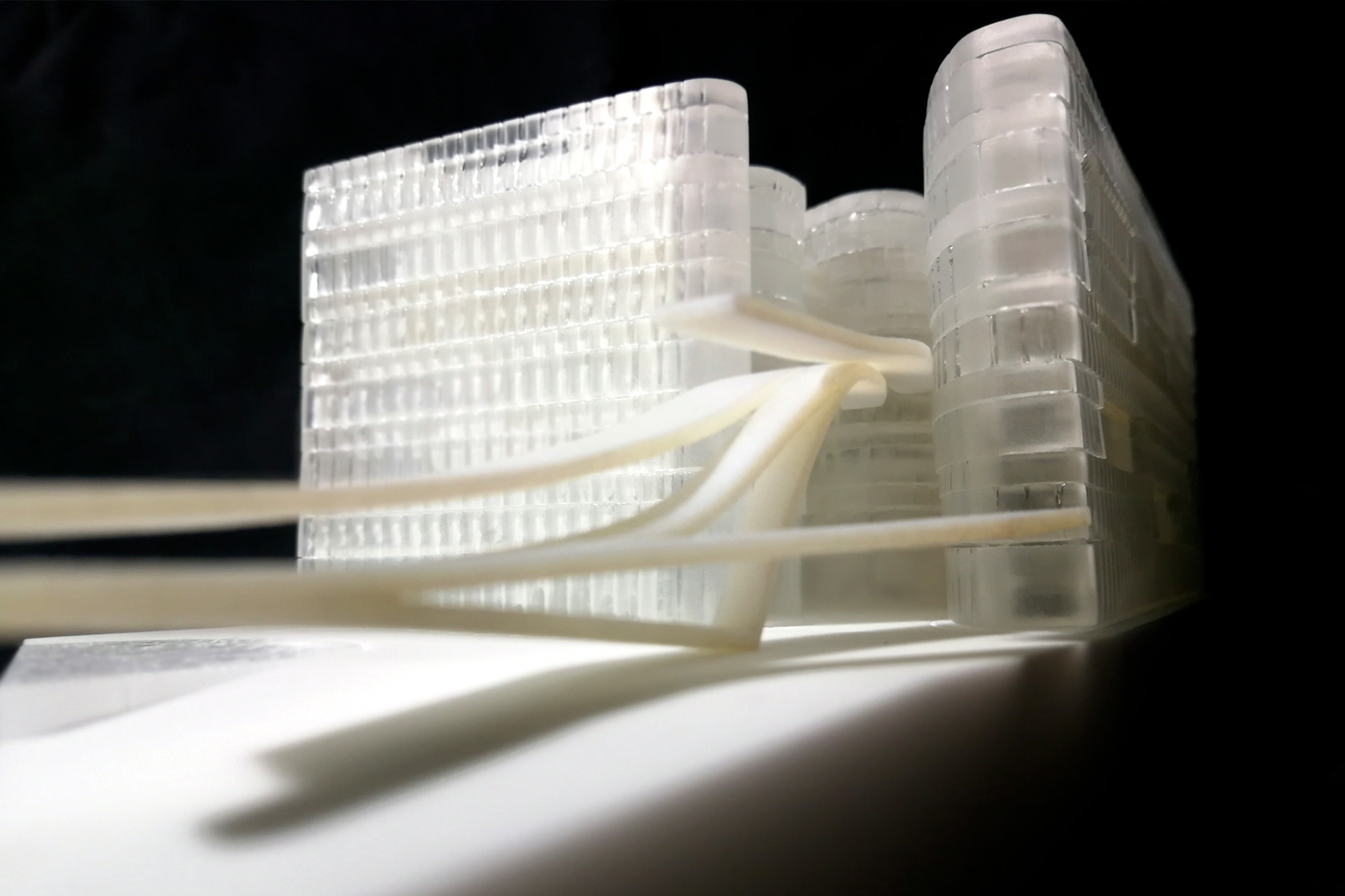

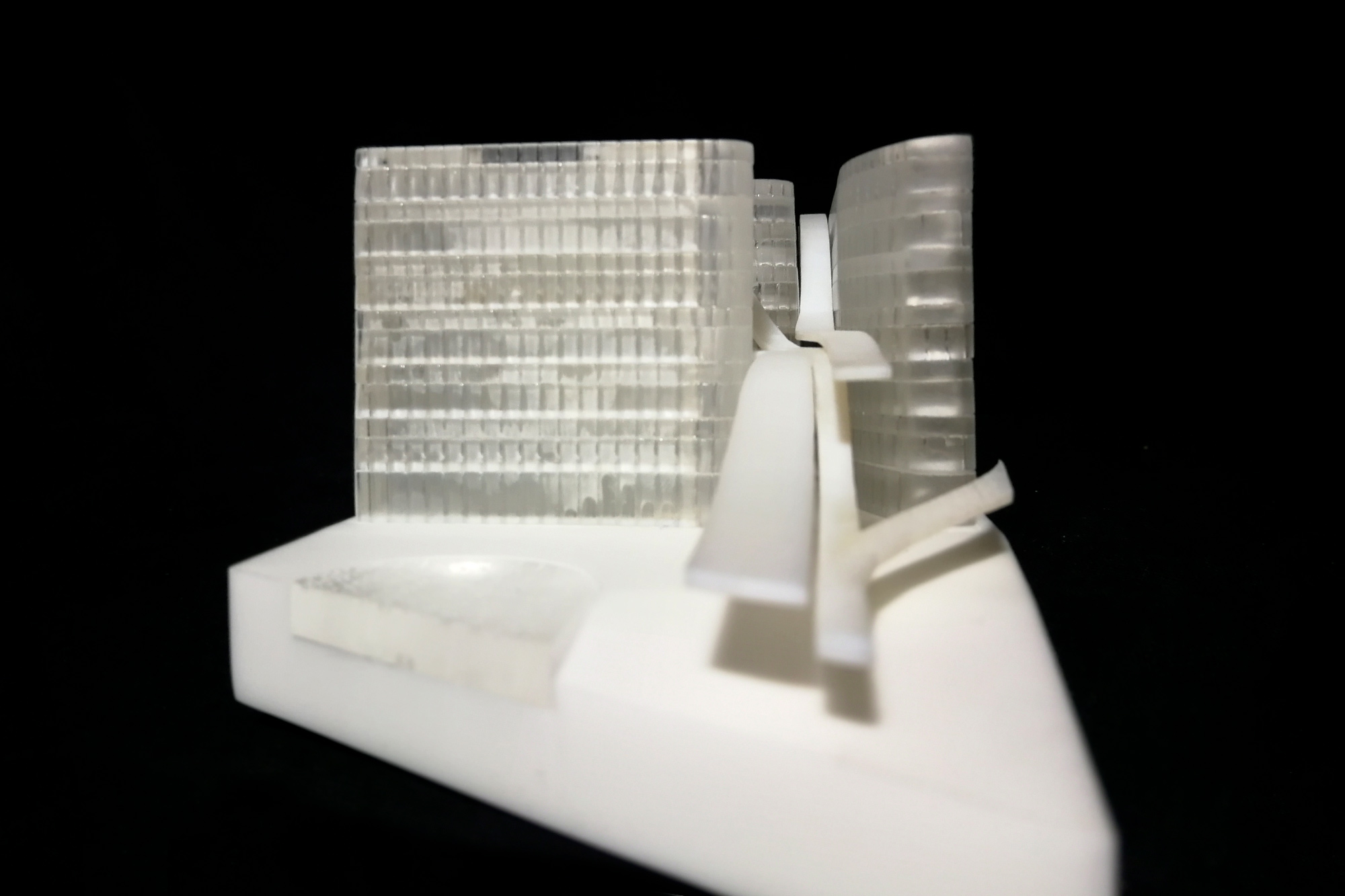

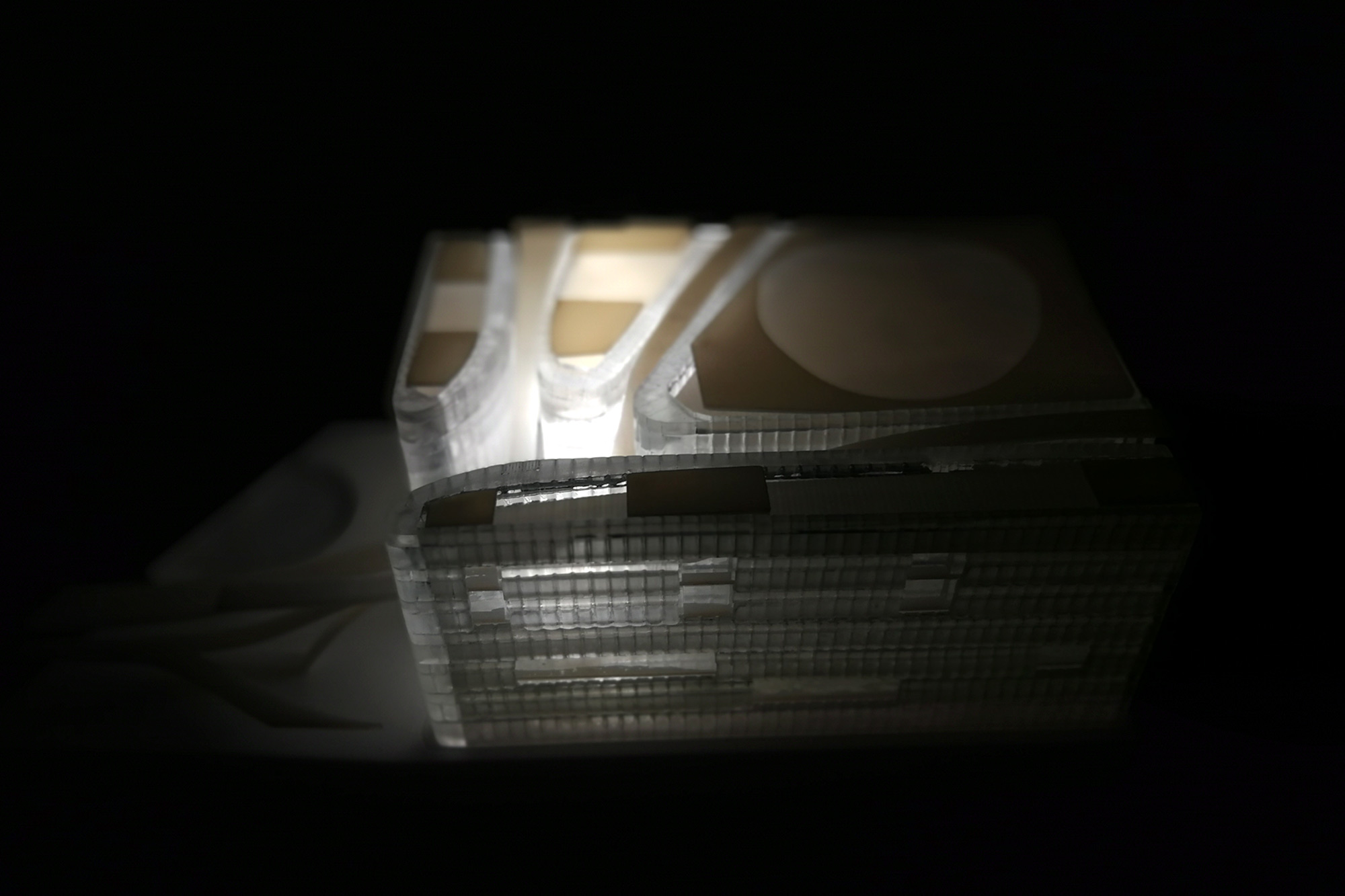

First of all, the premises of the drafting team were that the model should convey the sensation of lightness in its facade and flight as well as lightness in the pedestrian walkways. These pedestrian walkways cross the existing space between the different volumes and public spaces communicating them, from the squares to the rooftops.

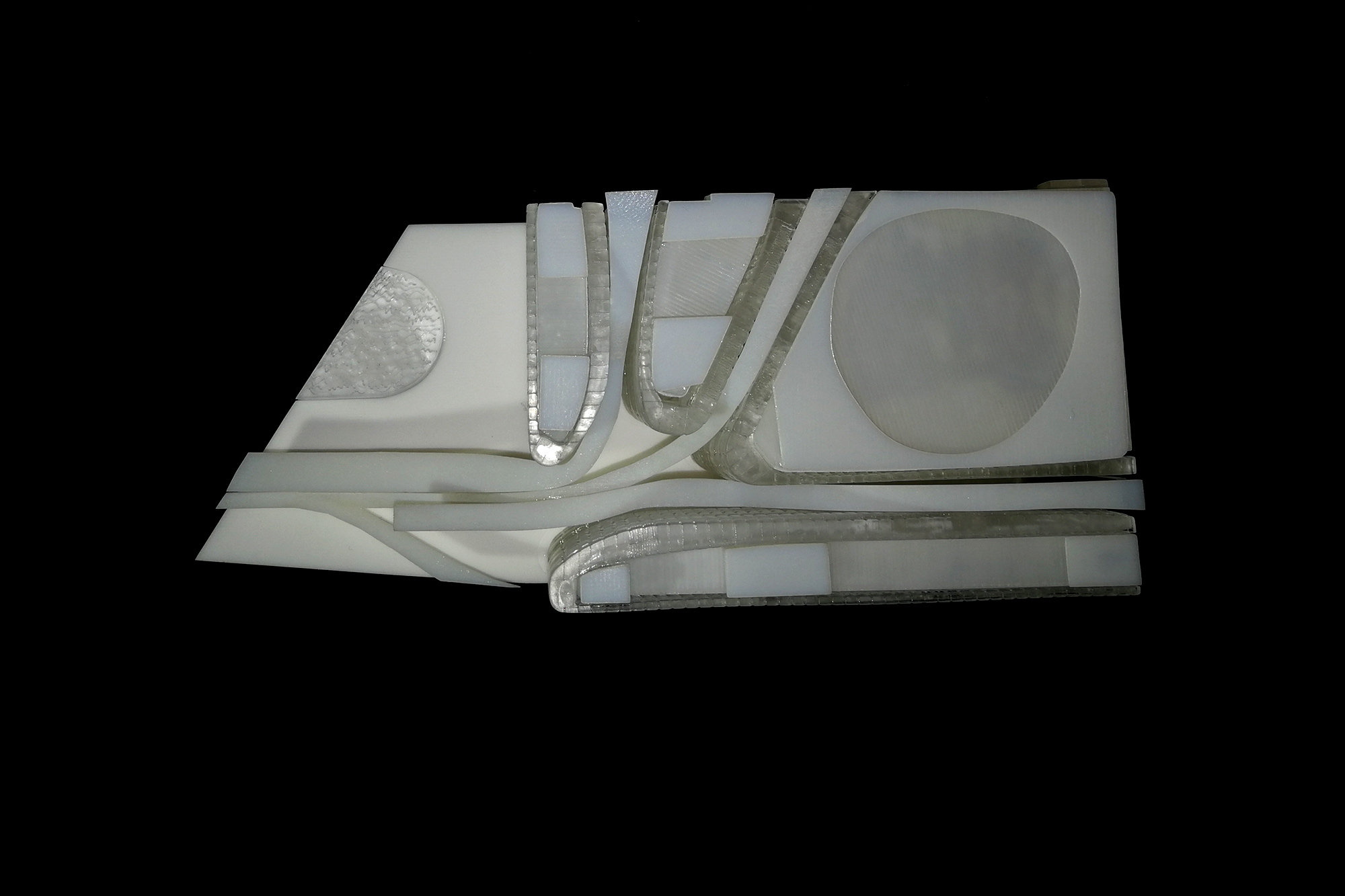

Our team opted first for the model of this international architectural competition II, for the realization of a base machined by CNC. For this base, we chose as material white methacrylate with the surrounding details.

Each of the four buildings that make up the project is divided into 3 clearly differentiated parts.

- The slabs are represented by 0.5 mm thick pieces 3D printed in ivory white resin.

- The ”habitable” space between floors is represented by 4 mm thick transparent methacrylate pieces.

- The façade, composed of two pieces of transparent methacrylate engraved with the project grid, is also divided into two ”levels” of 3 and 2 mm thick.

- The pedestrian walkways and sunshades on the roof were 3D printed in ivory white resin. The SLA 3D printing technique was also used for these parts.